The classification of domestic waste is not perfect at present, and the materials are still in a mixed state. To realize the recycling of domestic waste, the combustibles in it can be made into RDF fuel blocks for market needs. However, the materials are mixed with a large amount of kitchen waste and low calorific value and non-combustible materials such as porcelain pieces and stones. Therefore, before domestic waste is used as alternative fuel, it must go through a series of crushing and screening to separate the non-combustibles in it, and the remaining combustibles can be processed into high-calorific alternative fuel RDF.

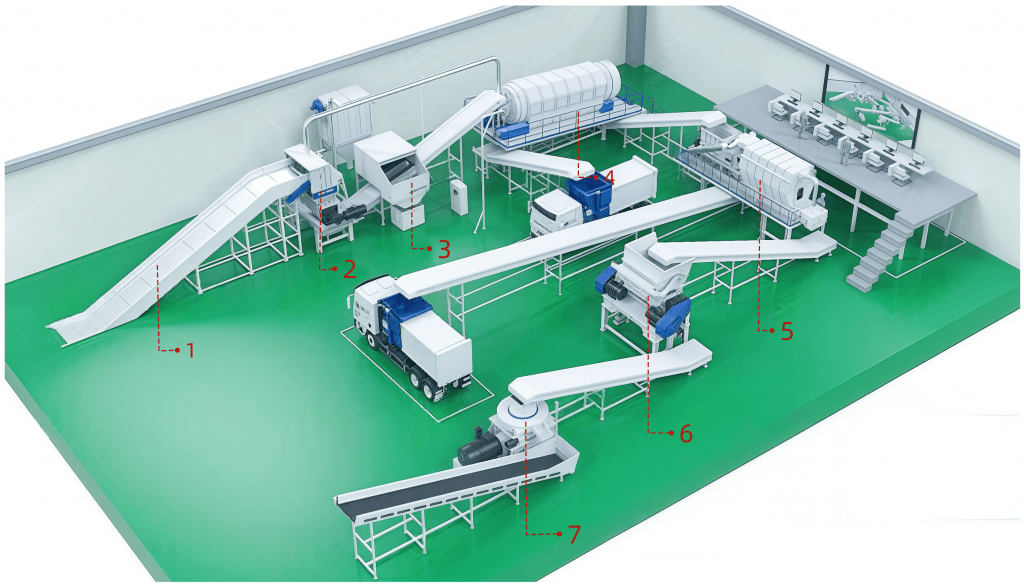

The main disposal process is as follows:

- Domestic waste is transported to the coarse crusher through a chain conveyor, and the coarse crusher tears and crushes the material;

- The crushed material is adsorbed by magnetic separation equipment to remove the ferromagnetic metal in the material;

- The remaining material enters the drum screen for screening to separate impurities such as kitchen waste, slag, and stones; kitchen waste can be made into humus soil through a high-temperature composting process;

- The screened material enters the air separator to sort out the non-combustibles;

- The combustibles will enter the single-axis fine crusher to crush the material to meet the back-end RDF briquetting molding;

- The crushed material can enter the RDF molding machine or the bulk material can be directly packaged.