Drum dryer

Drum dryer is a kind of contact internal heating and conduction drying machinery, which is widely used in chemical industry, brewing, manufacturing, pharmacy, fertilizer, municipal sludge treatment and other fields.

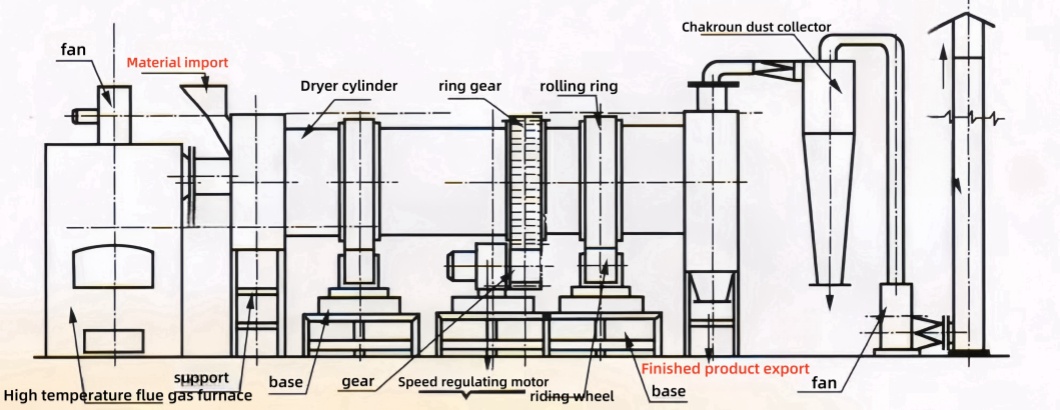

1. Working principle The drum of the drum dryer is a slightly inclined and rotatable cylinder. Wet materials enter from the upper part of one end and dry materials are collected from the lower part of the other end. Hot air enters from the feed end or the discharge end and is discharged from the upper part of the other end. The drum is equipped with a forward copying board, and the materials are constantly picked up and sprinkled during the rotation of the drum, which fully contacts with the hot air flow, thus improving the drying efficiency and making the materials move forward.

2. Main structure. The main components include roller, transmission device, heat source system, discharging mechanism, exhaust system and control system.

3. Features and advantages High efficiency: the drum dryer can dry a lot of materials in a short time, saving time and energy. Safety: the air is heated by heating elements and circulates through the drum, which will not cause damage to the materials and has fire safety protection devices. Convenient: the operation is simple. Users only need to put the materials into the drum dryer and set the drying time and temperature. Multifunctional: It has multiple drying modes and temperature control to meet the drying requirements of different materials. Large processing capacity, low fuel consumption, low drying cost and high temperature resistance, and can use high-temperature hot air to quickly dry materials. Strong scalability, the design takes into account the production margin, and there is no need to replace the equipment when the output increases slightly. The equipment adopts self-aligning tugboat structure, and the tugboat and the rolling ring cooperate well, which reduces the wear and power consumption.

4. Application field Drum dryer is not only used in the fields of biomass, chemical industry, brewing and pharmacy, but also widely used in metallurgy, building materials, coal washing, fertilizer, ore, sand, clay, kaolin, sugar and so on.

Product real shot

Raw material drying comparison

Delivery picture

Factory display