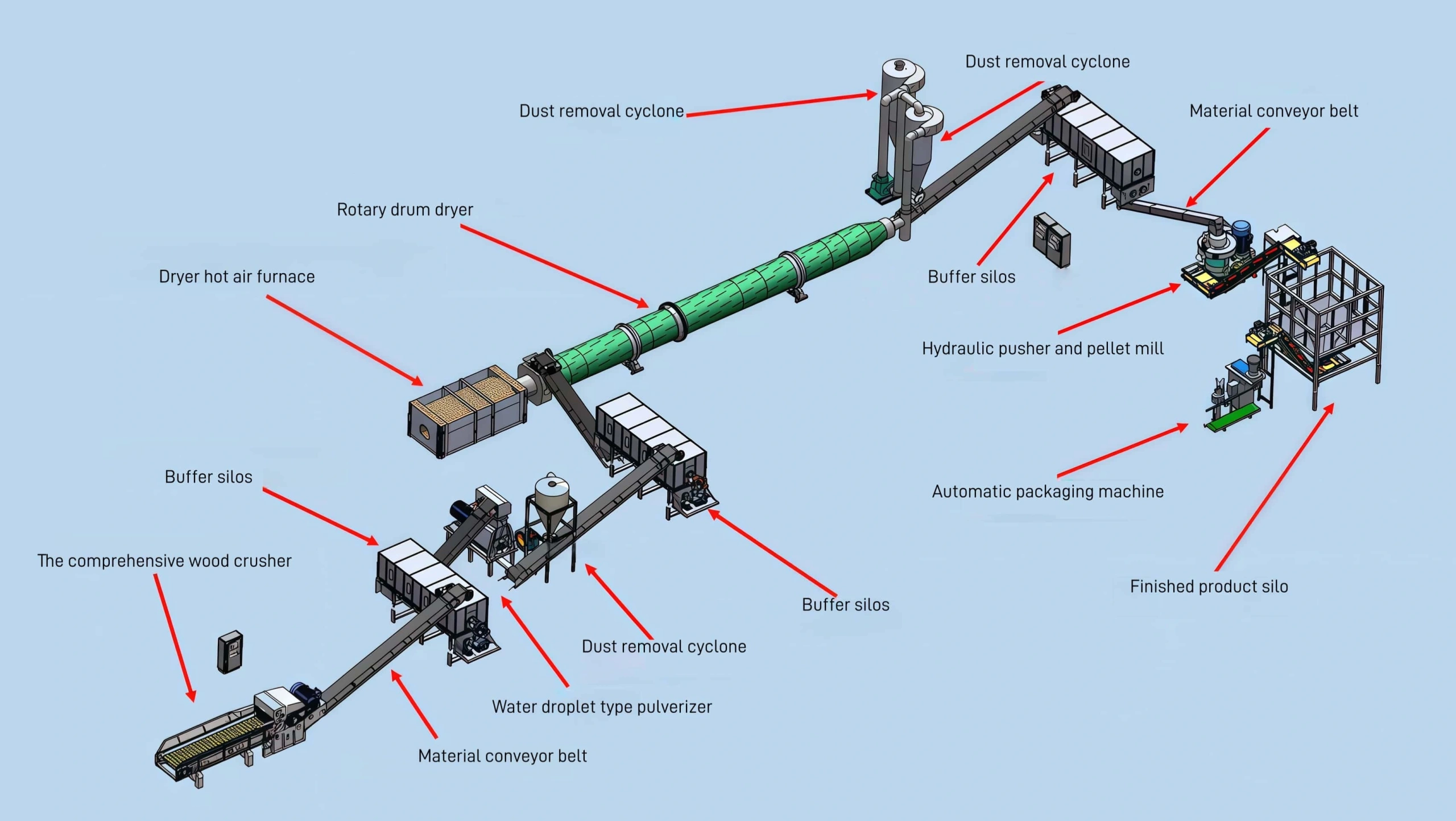

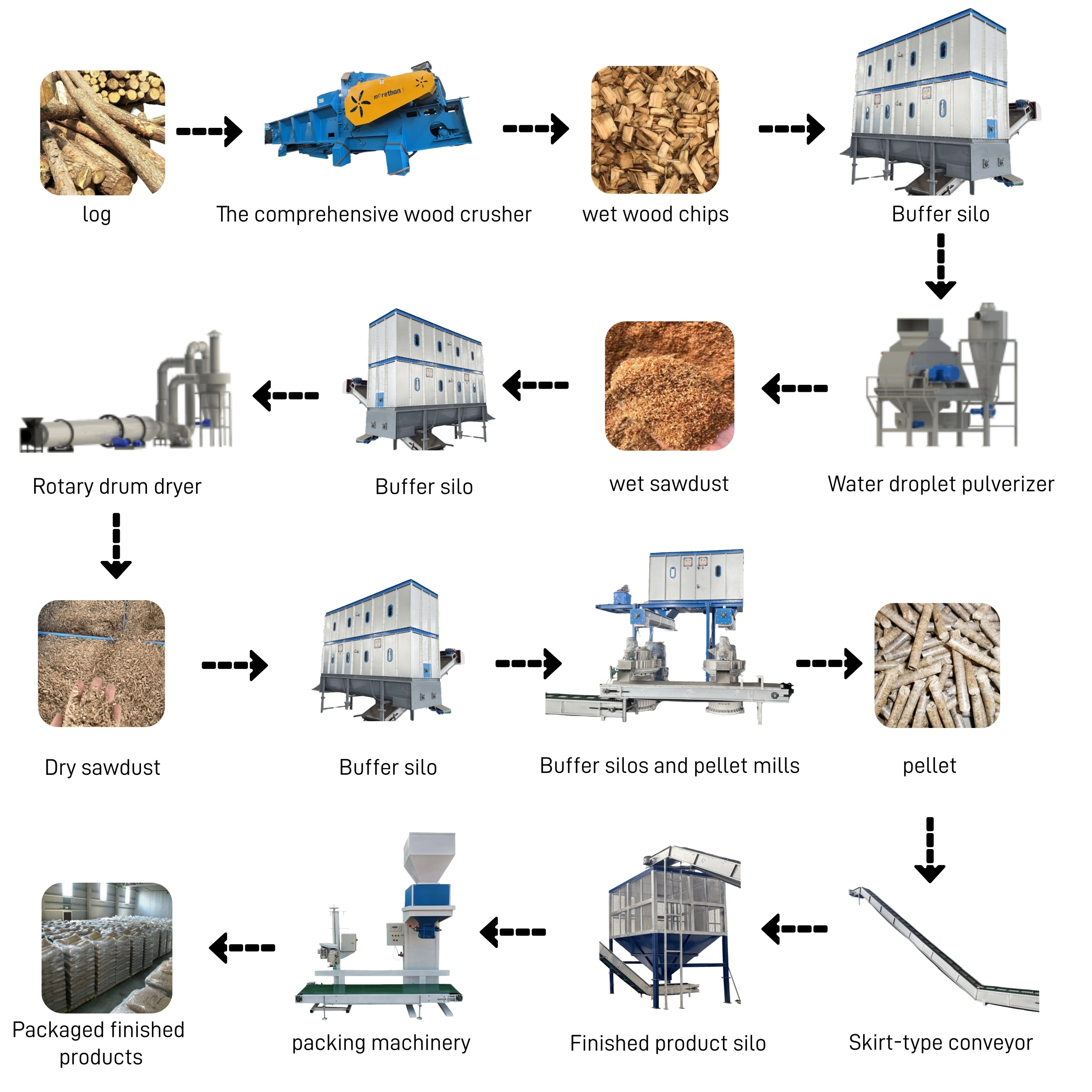

Biomass Ring Die Pellet Production Line

What you are seeing now is a complete 4-5 ton/hour automated biomass ring die pelleting production line. It includes a comprehensive crusher, wood chip hopper, water droplet pulverizer, sawdust hopper, drum dryer, dual-hopper feeder, two biomass ring die pellet mills, a cooling hopper, and a packaging machine. This system realizes the entire production process from raw material crushing, grinding, drying, pelleting, cooling to final packaging. The entire production line is designed to be automated, scientific, and continuous, producing high-calorific-value pellet fuel that is easy to store and transport. This production line has been exported to more than 50 professional biomass pellet energy plants worldwide.

In addition to our standard production lines, we specialize in crafting customized biomass pellet production lines with capacities ranging from 0.5 to 20 tons per hour.We offer complimentary layout planning and design based on your specific plant area, supported by installation guidance from our technical team—available both online and on-site to ensure a smooth project rollout. We welcome your inquiries.

Detailed introduction of each section of the production line

Crushing Stage:

The integrated crusher is the front-end equipment of the production line, primarily crushing various types of trees, small-diameter timber, logging residues (such as branches and twigs), and wood processing residues (such as bark, strips, log cores, veneer, etc.). It can also crush materials such as demolition waste, construction formwork, and urban recycling waste, as well as wood-iron mixtures containing nails, metal, and thin sheet metal. Furthermore, it can crush non-wood materials (such as hemp stalks, reeds, bamboo, corn stalks, and cotton stalks). Based on our company’s experience in manufacturing drum chippers, this machine was meticulously designed according to the characteristics of raw materials and the particle size requirements of biomass power plants. It features wide raw material adaptability, high output, reasonable structure, simple operation, safety and reliability, and convenient maintenance, making it an ideal integrated biomass crusher both domestically and internationally.

Fine Grinding Stage:

The teardrop-shaped pulverizer is a meticulously developed and standardized product of our company, primarily used for pulverizing various wood chips, wood strips, straw, weeds, etc. This series of teardrop-shaped pulverizers adopts direct-drive shaft transmission and a high-speed motor. The pulverizing chamber utilizes secondary impact technology, resulting in finer and more uniform particle size. Furthermore, the machine can rotate clockwise and counterclockwise, ensuring even wear of the pulverizing rotor and hammers, maintaining effective pulverization balance throughout use. This avoids structural issues reported by customers, such as high output and stable operation initially, followed by significant vibration and output decline after a few months. The main shaft bearing uses imported NSK high-quality bearings, and the main unit features a sliding door and elastic pressure screen structure, simplifying operation and maintenance. This machine boasts high output and low power consumption, capable of general pulverization as well as fine and micro-fine pulverization. It is widely used in large and medium-sized biomass pellet plants, feed mills, citric acid plants, food factories, and other industries.

Drying Stage:

The stacked high-efficiency rotary drum dryer differs from traditional airflow dryers, single-drum dryers, three-pass dryers, three-cylinder dryers, and vacuum dryers. It overcomes many shortcomings of other models, such as the low output of airflow dryers, the low thermal efficiency of single-cylinder dryers, the ignition susceptibility of three-pass dryers, the slow discharge speed and low air pressure of three-cylinder dryers, and the high cost and large footprint of vacuum dryers. Its thermal efficiency ratio is currently industry-leading both domestically and internationally, based on real customer feedback, reaching up to 1:12.5. Furthermore, it can be designed with various combustion methods according to user needs, including biomass burners, log combustion chambers, wood chip combustion chambers, and natural gas. The working principle of the rotary drum dryer is to dry sawdust through hot air and mechanical motion. First, hot air is generated in the combustion chamber and sent into the drum. The material undergoes mechanical motion inside and outside the drum, allowing for full contact and conduction of hot air and moisture, thereby evaporating the moisture in the sawdust and achieving the drying effect.

Pellet production stage:

The vertical ring die biomass pellet mill is a meticulously developed product series by our company. It incorporates the best features of pellet mills both domestically and internationally. Its core component is a “two-layer mold, integrated through-shaft, two fixed and two vertical transmission” assembly structure, ensuring stability and scientific design. The pressure roller is made of high-alloy wear-resistant material, resulting in a lifespan several times longer than similar products. The transmission structure features automatic grease filtration for thorough lubrication. It boasts a unique design, reasonable structure, low energy consumption, high efficiency, and robust wear resistance.

Applicable raw materials include, but are not limited to: wood (pine, poplar, fir, branches, bark, sawdust, shavings, etc.), straw (corn stalks, wheat stalks, rice straw, rice husks, peanut shells, cotton stalks, etc.), and waste materials (construction templates, furniture scraps, wooden pallets, municipal waste, medicinal residue, mushroom residue, sludge, etc.).

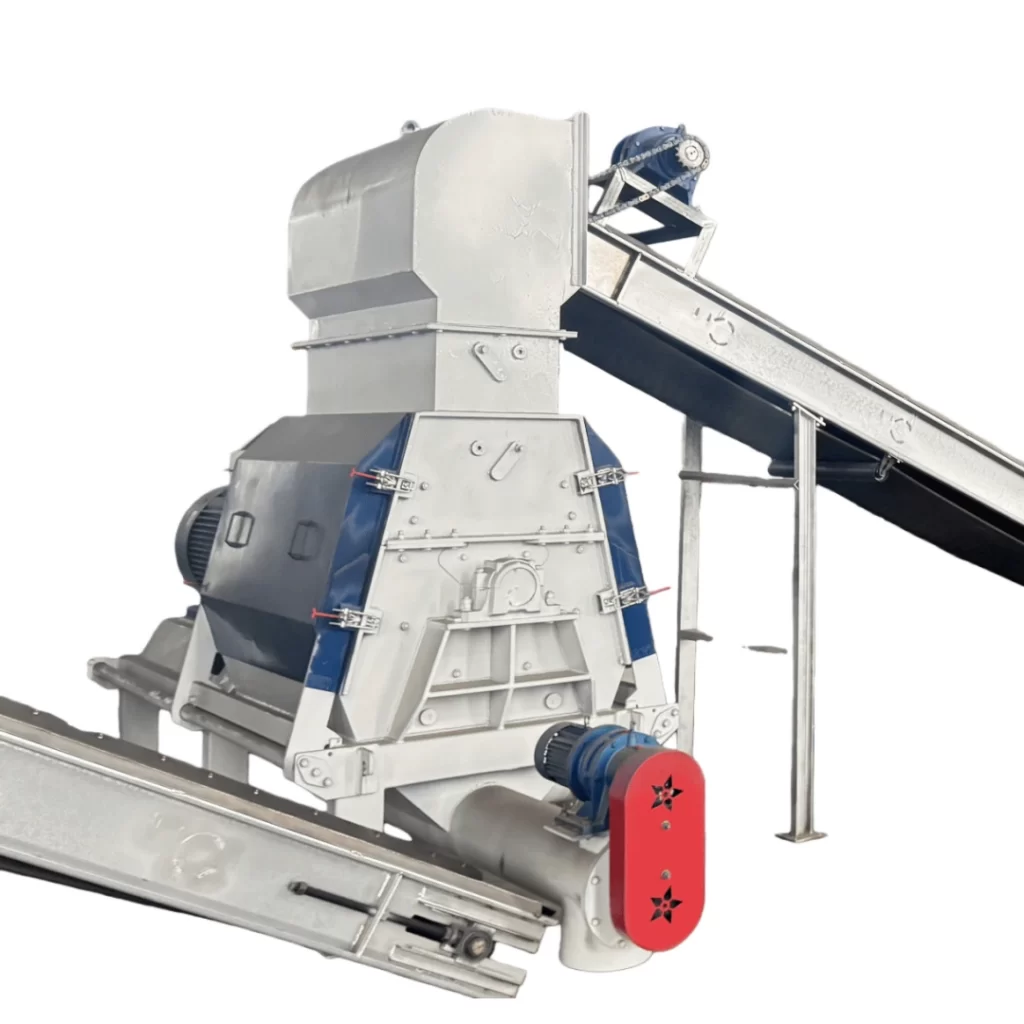

1.The comprehensive wood crusher

The comprehensive wood crusher is the key equipment of the whole line of the ring mould particle production line, which can be used to treat all kinds of wood waste, including branches, waste wood, wooden pallets and so on. The equipment is equipped with efficient and powerful cutting system, combined with well-designed structure, which can break raw materials into uniform and fine wood chips to meet the processing needs of subsequent sections.

2.Buffer silos

The storage silo is used to buffer the crushed wood chips. Variable frequency speed control can control the discharge. It is equipped with a variable frequency control cabinet, loading and unloading limiters, dust explosion-proof windows, etc.

3.Water droplet type pulverizer

This high-performance teardrop-shaped pulverizer is suitable for a wide variety of materials. Its wear-resistant and sharp alloy blades extend the equipment’s lifespan. The pulverizing chamber employs a multi-stage crushing and fine-crushing mechanism, resulting in high impact force, high production efficiency, and strong fine-crushing capability. The hammer blades are coated using a tungsten carbide spray welding process, allowing for multi-faceted use, which improves production efficiency and reduces operating costs.

4.Rotary drum dryer

The dryer adopts a drum drying mode, using wind power to discharge raw materials with acceptable moisture content in sequence, ensuring effective use of heat source, and can increase output by 15% compared with traditional dryers. During the material collection process, gravity is used to separate impurities and metallic materials from the raw materials, thereby reducing the wear of the pellet mill during pelleting and reducing the ash content of the finished pellets.

5.Hydraulic pusher and pellet mill

The hydraulic feeder evenly distributes material to two pellet mills, and includes a frequency converter cabinet, loading and unloading limiters, and dust explosion-proof windows.The pellet mill’s feed inlet and discharge hood are made of stainless steel, which is lightweight, durable, and corrosion-resistant. The die features a feeding hole-forming hole-forming hole-releasing hole design, minimizing forming and discharge resistance. Electrical components are from top-tier companies like Chint and Delixi, and the reducer uses heavy-duty hardened gears. The die is made of 20CrMnTi material with a carburized surface treatment to improve service life, and the pressure rollers are made of 65 manganese steel.

6.Finished product silo

Finished product silos are used for centralized storage and heat dissipation of finished product granules.

7.Automatic packaging machine

Automatic packaging machine packages finished pellets, integrating automatic weighing, packaging, and conveying functions.

8.Material conveyor belt

The conveyor belts are used to transport materials between equipment. This production line uses a total of 8 conveyor belts, located at the rear end of the integrated crusher, the rear end of the No. 1 transfer buffer silo, the rear end of the teardrop-shaped crusher, the rear end of the No. 2 transfer buffer silo, the rear end of the drum dryer, the rear end of the No. 3 transfer buffer silo, the rear end of the pellet mill, and the rear end of the finished product silo.

9.Finished biomass pellets

Finished biomass pellets boast the golden selling points of “high energy, easy to sell, and clean and environmentally friendly.” Pellet fuel has a high energy density, comparable to coal; its regular shape facilitates long-distance transportation and long-term storage, making it easy to enter the energy market; more importantly, as a clean and renewable energy source, it burns cleanly and is strongly supported by environmental protection policies, making it an ideal alternative to coal.

FAQ

Q: What are your payment methods?

A: We support TT wire transfer, credit cards, and various electronic payments.

Q: What are your main markets?

A: Europe, America, Southeast Asia, Africa, Oceania, etc.

Q: What is your production cycle time?

A: The production cycle depends on the machine model you order, and usually takes 45 days.

Q: What documents can you provide?

A: We can provide invoices, packing lists, contracts, instruction manuals, customs declarations, certificates of origin, and CE certification. If customers require other documents and specifications, please confirm with customer service.

Q: How do you handle equipment quality issues?

A: We will take responsibility for all quality issues. We will inspect the machine to find the problem. If you need spare parts, we will send them to you.

Q: What is the warranty period?

A: One year. (Damage to consumable parts is not covered under warranty and requires the purchase of additional parts.)