Ring Die Biomass Pellet Machine

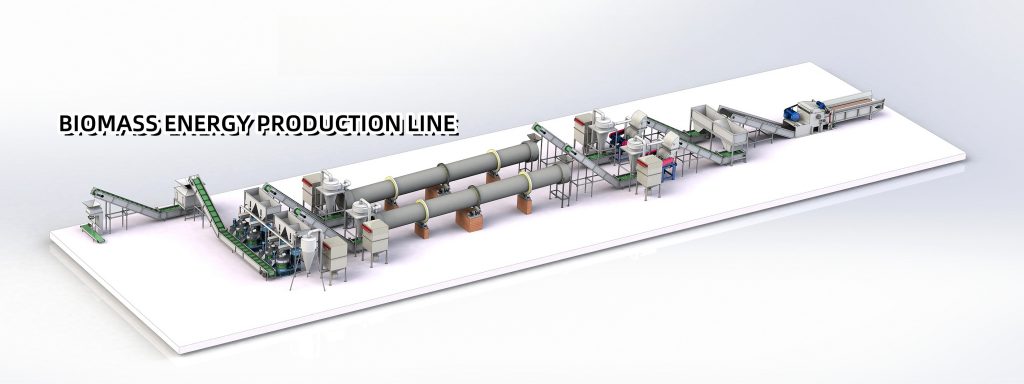

The Ring Die Biomass Pellet Machine is mainly used to produce biomass pellet fuel, which is environmentally friendly and renewable and is widely used in industrial and civil fields. It mainly works with crushers, dryers, coolers, packaging machines, etc.

The workflow is as follows:

1. Raw material pretreatment (crushing, drying). Use a crusher to crush biomass raw materials (such as pine, poplar, fir, branches, bark, shavings, corn stalks, wheat straw, alfalfa, straw, rice husks, coconut shells, palm shells, betel nut shells, peanut shells, bamboo, building templates, furniture scraps, wooden pallets, urban garbage, etc.) to 8-12 mm. After crushing, use a dryer to dry the raw materials to a moisture content of 20-50%.

2. Production stage. The dried biomass powder is fed into the biomass pellet machine for granulation production.

3. Cooling stage. Through the cooler, the temperature of the generated biomass pellets is reduced from 70-80ºC to 20ºC to prevent cracking due to excessive temperature.

4. Packaging stage. Automatic packaging and sealing machines are used to weigh and package the products for easy storage, transportation and sales.

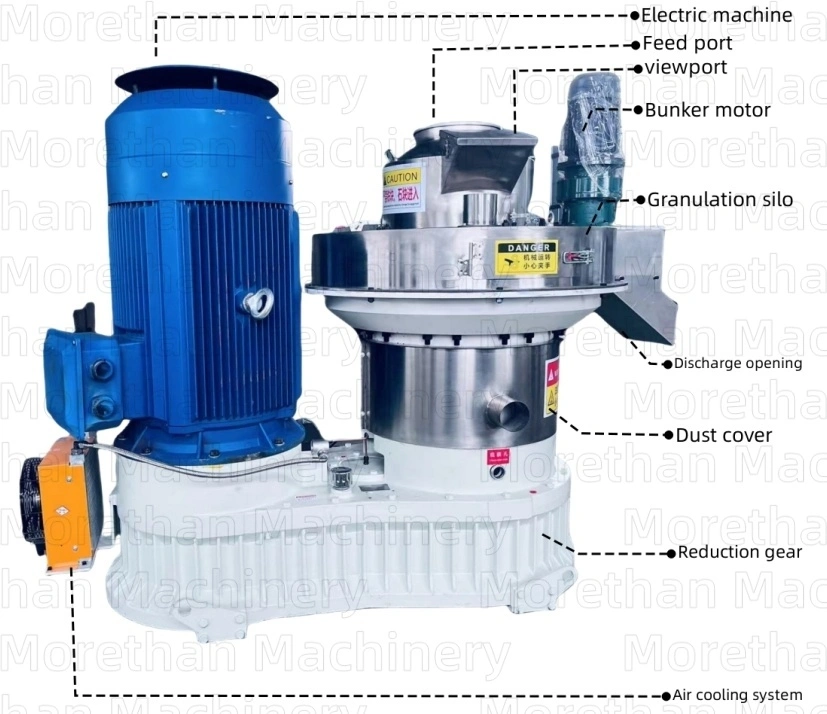

Ring die biomass pellet machine has high output, high pressure, high speed and wide applicability.

It is mainly used to convert agricultural and forestry wastes such as wood chips, straw, rice husks, bark, corn cobs, peanut shells, waste furniture, bamboo, waste logs, packaging boxes, etc. into high-density pellet fuel.

The working principle of the ring die biomass pellet machine is to gradually form cylindrical pellets under the extrusion and friction of the high-speed rotating ring die and pressure roller.

Product model introduction

| Model | Weight | Capacity | Power | Parts |

| 300MTRD | 600 kg | 0.2-0.4 t/h | 22 kW | pelletizer ,electric control cabinet |

| 400MTRD | 1050 kg | 0.4-0.6 t/h | 37 kW | |

| 450MTRD | 2500 kg | 0.6-0.8 t/h | 55 kW | Complete set including 1.pellet mill 2.cyclone system to remove dust 3.4 meter screw conveyor 4.electric control cabinet 5.automatic lubrication oil system |

| 470MTRD | 4000 kg | 0.8-1 t/h | 75 kW | |

| 560MTRD | 5600 kg | 1.2-1.5 t/h | 90 kW | |

| 580/600MTRD | 6500 kg | 1.8-2 t/h | 110 kW | |

| 650MTRD | 7000 kg | 2-2.5 t/h | 132 kW | |

| 700MTRD | 8000 kg | 2.5-3 t/h | 160 kW | |

| 760MTRD | 8600 kg | 2.8-3.2 t/h | 185 kW | |

| 850MTRD | 9500 kg | 3.5-4 t/h | 220 kW | |

| 880MTRD | 10000 kg | 4.5-5 t/h | 250 kW |

Buying a stand-alone machine includes the following accessories:1.cyclone system to remove dust;2.electric control cabinet ;3.screw conveyor for feeding ;4.automatic lubrication system

Product details

Factory display

Delivery site

FAQ

1. Could I have prices of your products ?

Welcome. Pls feel free to send us an email here. You will get our reply in 24 hours.

2. Can we customize our logo/website/company name on products?

Yes, we offer OEM and ODM service.

3. Can I get a discount?

Yes, the more quantity, the better the price. Please contact us to get the best price.

4. Do you inspect the finished products?

Yes, each step of production and finished products will be came out inspection by QC department before shipping.

5. Where are you? Can we go to China and visit your factory?

Yes, of course. We are in Henan, China. Welcome to our factory.